Introduction: A Quiet Revolution in Workholding

In the landscape of modern manufacturing, some innovations make loud headlines—artificial intelligence, robotics, or additive manufacturing. Others, while quieter, fundamentally reshape the way factories operate. One such technology is the self-centering vise. Though it may not appear glamorous at first glance, this humble workholding tool is becoming a cornerstone of smart manufacturing and Industry 4.0.

Over the last decade, as manufacturers have moved toward automation, flexible production, and high-precision machining, the need for reliable, efficient, and intelligent clamping systems has grown. Self-centering vises are answering that call, providing both mechanical simplicity and strategic advantage.

What Is a Self-Centering Vise?

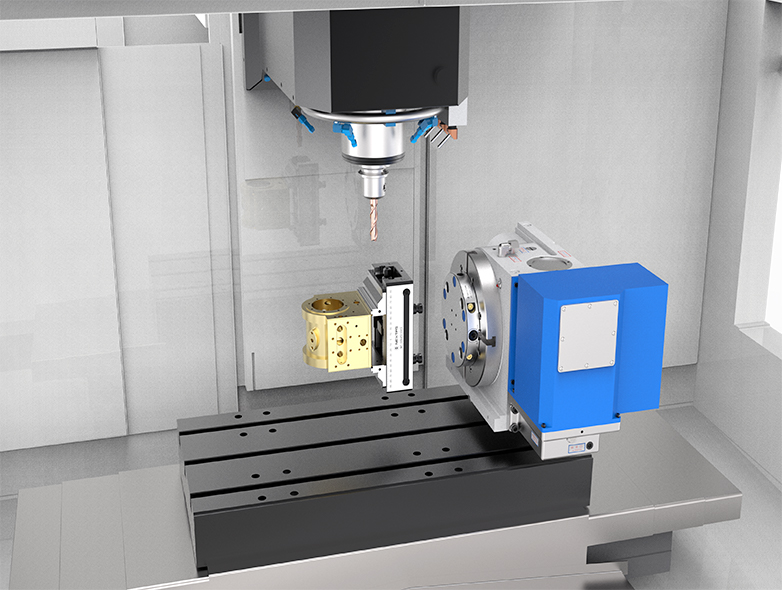

At its core, a vise is a device that holds a workpiece in place during machining. Traditional vises typically require manual adjustments, often leading to wasted time, uneven clamping, and human error.

A self-centering vise is different. It uses a synchronized mechanism to automatically align the workpiece to the center. No matter the size (within its range), the jaws move symmetrically, ensuring the workpiece is perfectly centered every time.

This might sound simple—but in practice, it eliminates minutes or even hours of setup, improves repeatability, and directly enhances machining precision.

Why Now? Market Drivers Behind the Trend

Several forces are driving the widespread adoption of self-centering vises:

- Automation & Robotics

In automated production lines, consistency is non-negotiable. Robots don’t “eyeball” adjustments—they require fixtures that guarantee repeatable alignment. Self-centering vises integrate seamlessly into robotic loading systems. - High-Mix, Low-Volume Production

Mass production is no longer the dominant model. Factories increasingly produce customized parts in smaller batches. A workholding solution that adapts quickly is critical—and self-centering vises excel here. - Precision Requirements

Aerospace, medical devices, and EV components demand extreme accuracy. Even small alignment errors can lead to costly defects. Self-centering mechanisms reduce such risks dramatically. - Cost Pressure

Reducing setup time saves labor. Minimizing scrap saves materials. In a hyper-competitive environment, small efficiencies add up to big advantages.

Case Snapshots: Industries Embracing the Change

- Aerospace: Manufacturers machining turbine blades use self-centering vises to ensure symmetry, cutting inspection times nearly in half.

- Automotive: EV battery tray production has shifted toward flexible vises to handle diverse geometries.

- Medical Devices: Orthopedic implant manufacturers rely on perfect repeatability to meet strict FDA quality standards.

Self-Centering Vises in the Context of Smart Manufacturing

Smart manufacturing isn’t only about digital tools—it’s about connectivity, intelligence, and adaptability. Self-centering vises align with this vision in several ways:

- Integration with Sensors: Some modern vises include sensors to monitor clamping force, feeding data into digital twins.

- Modular Design: Interchangeable jaws expand versatility, allowing rapid changeovers in automated cells.

- Predictive Maintenance: With IoT integration, a vise can signal when its mechanism needs service, preventing downtime.

Challenges Ahead

No trend is without hurdles. Self-centering vises face:

- Initial Investment Costs: More expensive than traditional vises, requiring ROI justification.

- Education & Training: Operators and engineers need to adapt to new workflows.

- Compatibility Issues: Not all cnc with 4th axis machines or robotic systems support easy integration.

The Future Outlook

Looking forward, experts predict that 5th axis vises will become the default choice in automated workshops within the next decade. As machine tools become more intelligent, vises will no longer be “dumb” fixturing clamps but active contributors to smart production ecosystems.

Expect to see:

- Vises connected to MES/ERP systems.

- Adaptive jaws capable of handling irregular geometries.

- AI-driven optimization of clamping forces based on workpiece material.

Conclusion

The rise of self-centering vises reflects a broader truth: sometimes, it’s not the flashy technologies but the quiet enablers that truly power transformation. As factories evolve into smart manufacturing hubs, workholding is no longer just a detail—it’s a strategic advantage.

The next time you hear about automation breakthroughs, remember: behind the robot, behind the CNC spindle, there may be a self-centering vise quietly making it all possible.